Asia Pacific Coatings Show (APCS 2023) will be held in Bangkok, Thailand, on September 6-8, 2023. As the most famous and influential coatings exhibition in the Asia-Pacific region, the show is hosted by dmg Events (mea) Ltd., a well-known media and exhibition company in the UK. Since 1991, it has been held annually in Thailand, Indonesia, West Asia, and other countries. The exhibition has returned to Thailand again this year since the last time it was successfully held in 2009.

As a leading show for raw material suppliers and equipment manufacturers in the coatings industry in Southeast Asia and the Pacific Rim, Asia Pacific Coatings Show promotes the latest coatings and coating technologies to meet the region’s environmental, manufacturing, and industrial needs and provides an excellent development opportunity for international coatings industry personnel.

Sidley Chemical, a new material company, has been active on the stage of the international coatings show. This time, we will bring various innovative solutions for dry-mixed mortar additives and demonstrate green and innovative manufacturing technologies to the Southeast Asian coatings market in an all-around way. Help Customers customize products to enhance the value of products and services!

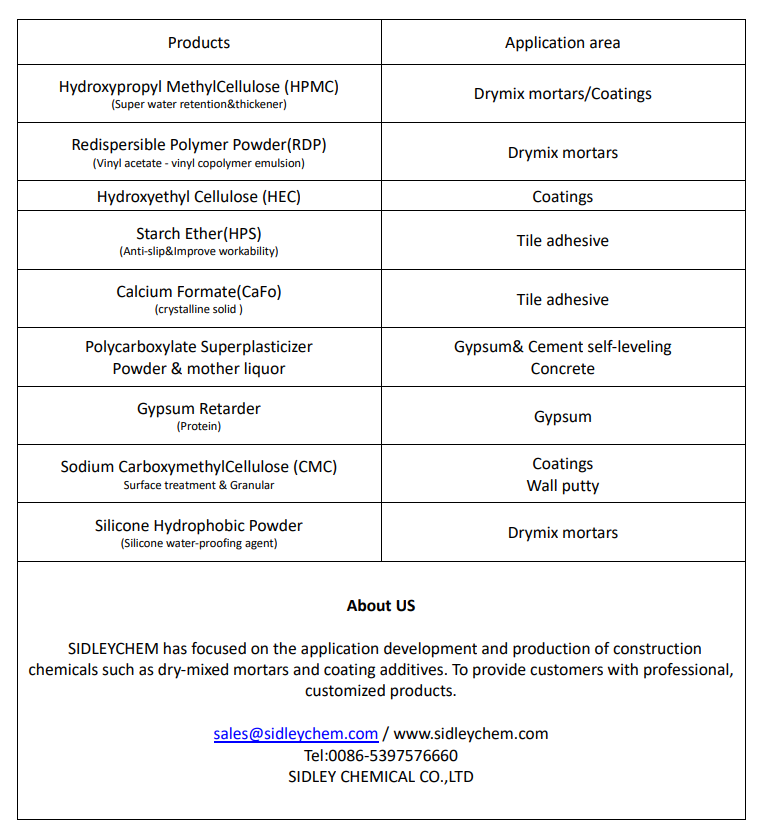

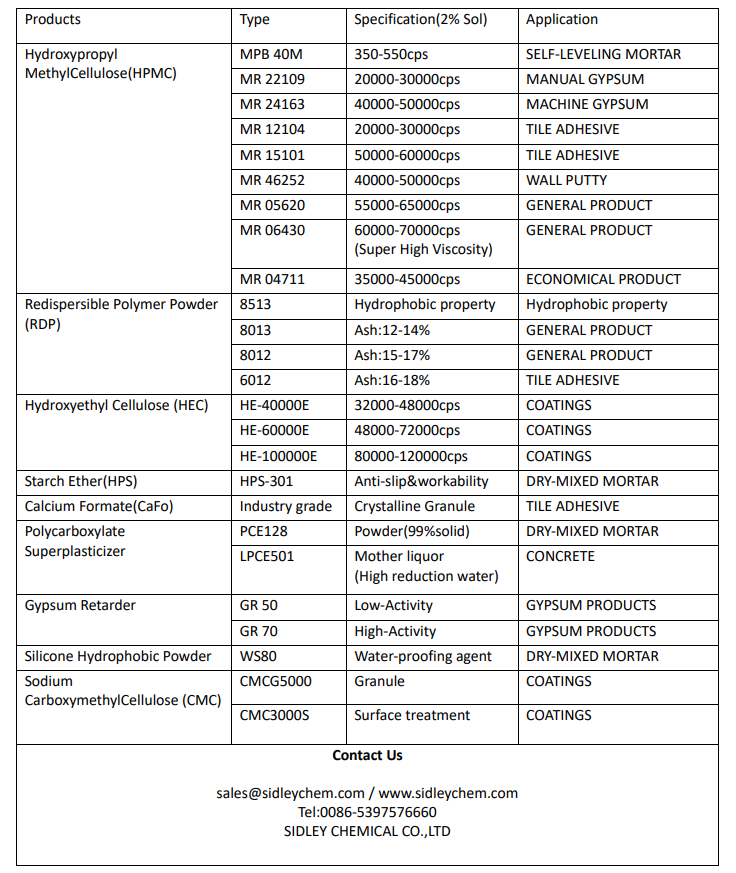

Exhibit preview

HPMC is an essential additive in dry-mixed mortar and has extensive uses in the building materials industry. It is vital in tile adhesive, ready-mixed mortar, putty, and gypsum. We provide various functional cellulose ether by adjusting the production process to help customers improve their performance and make them more competitive.

Sodium carboxymethyl cellulose ( CMC ) is an anionic cellulose ether product made from natural cotton fiber as the primary raw material through alkalization, etherification, purification, drying, crushing, or granulation. The appearance of CMC is white powder or granules, and its water-soluble colloid has the functions of thickening, stabilizing, emulsifying, suspending, and film-forming. They are widely used in food, toothpaste, paper, ceramics, printing and dyeing, oil drilling, and other industries.

RDP is a significant mortar additive produced by Sidley which can improve mortar strength and weather resistance with excellent adhesion to various substrates. It is an indispensable additive in dry-mixed mortar. The RDP is made of Celanese emulsion, which forms a free-flowing white powder after spray drying. The powder can form a stable dispersion after being stirred with water, and its properties are similar to those of the original emulsion. That is, after the water evaporates, a film is formed. This film has high toughness and excellent adhesion to various substrates. They are widely used in external wall insulation, tile adhesive, putty, and other products. We recommend RDP-8044, 8013, 6013, and other products to customers that are suitable for mortar systems.

Polycarboxylate superplasticizer has ultra-high water reducing rate, excellent concrete slurry state, linear slump loss, suitable for customer on-site mixing and prefabricated parts factories. Recommended model: PCE154L

Polyester fiber has the advantages of high strength, corrosion resistance, high-temperature resistance, strong chemical stability, and binding solid force with asphalt. When added to asphalt concrete, it forms many three-dimensional random distributions of fiber monofilaments after stirring, which can effectively improve the mechanical properties of asphalt mixture and prevent the cracking of asphalt concrete.

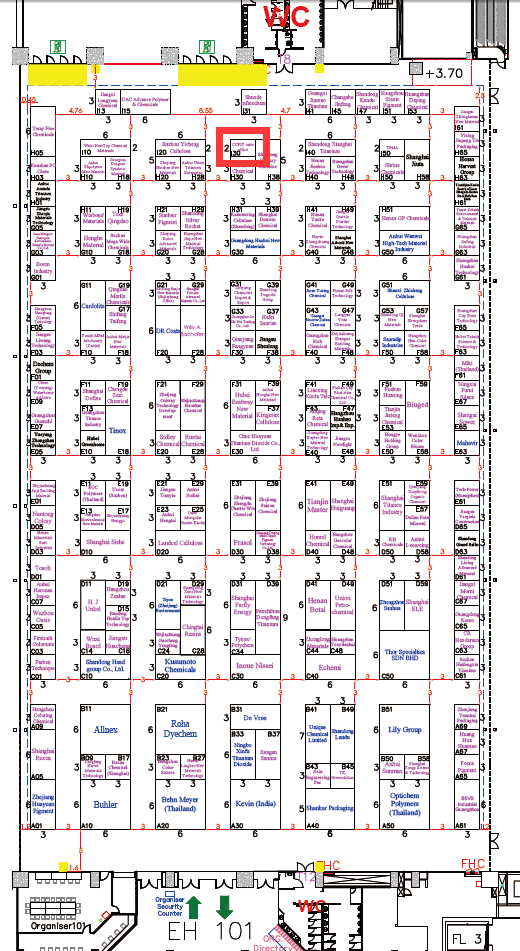

More product information can be found at booth E20! Welcome everyone to join us! We will see you there!

We will bring the following products along to the coatings show: